New Solar Energy Dye Soon To Be Embedded In Hundreds Of Consumer Products

March 14, 2008 at 2:24 pm 1 comment

Organic photoelectrochemical, dye-sensitized cells, a new type of solar energy, is expected to hit the market this Summer. The technology, which is easy and cheap to use, will be embedded in hundreds of day-to-day consumer products. The dye cells can be used for windows, building facades, gadgets and even in clothing. The pioneer behind the technology is a Swiss professor named Michael Gratzel, who claims that his invention is more robust than regular photovoltaic panel solutions.

Organic photoelectrochemical, dye-sensitized cells, a new type of solar energy, is expected to hit the market this Summer. The technology, which is easy and cheap to use, will be embedded in hundreds of day-to-day consumer products. The dye cells can be used for windows, building facades, gadgets and even in clothing. The pioneer behind the technology is a Swiss professor named Michael Gratzel, who claims that his invention is more robust than regular photovoltaic panel solutions.

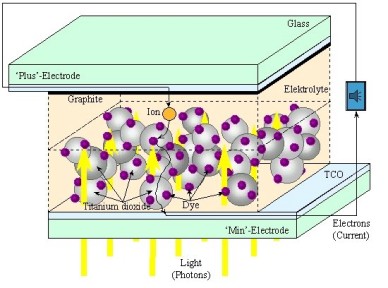

Dye based solar cells are made of titanium oxide nanochrystals. These are coated with light absorbing dye that can be used in various materials including glass and plastic. The dye is immersed in an electrolyte solution. When light reaches the surface, the dye sets free electrons which in turn create ‘holes’ – positive charges as a result of ‘lost electrons’. The titanium dioxide semiconducts and transfers electricity to an electrical circuit and energy is created.

The solar cells convert light to electricity with an efficiency of 7.2 percent, which is a record for this type of cell. Solar panels typically convert 16 percent to 20 percent of light into energy. But the advantage of the organic dye cells is that they also convert low light and that they can be ‘tuned’ for specific wavelengths.

The first company manufacturing dye sensitized solar cells is Konarka, which is based in Lowell, MA. This company announced it had successfully conducted the first-ever demonstration of manufacturing solar cells by highly efficient inkjet printing ten days ago. Konarka is focusing on getting the technology embedded in hundreds of day to day products. In the Summer Konarka is planning on shipping out its first products, mainly gadgets, lights and smart cards.

One drawback of the solution’s first editions was that the electrolyte could start to leak in cases of high temperatures. This has been redressed by altering the electrolyte liquids. Grätzel and his team refined this original design by optimising the sensitiser and using organic dyes based on indoline. This allows the titanium oxide to be thinner, which reduces the electron path length.

Michael Gratzel explained in a recent scientific paper published in Inderscience’s Angewandte Chemie how he’s sophisticated his technology.

Entry filed under: Green Health, Green Marketing, Green Scientific Discoveries, The Planet's Resources. Tags: cell based dye, organic solar dye, photovoltaic, solar energy.

My StumbleUpon Page

My StumbleUpon Page

1. FRANK COLSON | March 15, 2008 at 6:08 pm

FRANK COLSON | March 15, 2008 at 6:08 pm

Well suited for a broad range of applications I presume.

Please forward additional data to”

Colson EnergySolutions

artact@co9mcast.net

Thank you

Frank Colson